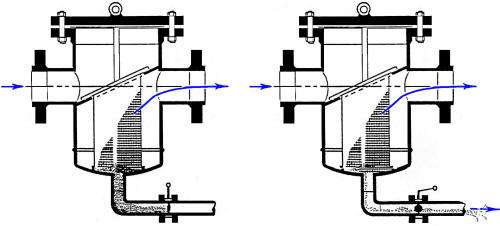

Akin to the blow down feature of a Y strainer, flushing strainers are a variation of a standard simplex basket strainer having a special "bottomless" basket which allows accumulated particles to "flush" from the drain port when a valve is opened. We can include the manual or actuated valve within our scope of supply.

Although the actual flushing of the strainer basket typically requires less than 1-2 seconds, if you use an automated valve the flushing time will be dependent upon the cycle time of the valve actuator, which is typically 18 to 30 seconds from closed, to open and then back to closed.

Although tempting and beneficial for some applications, automating the flushing feature will likely require a custom programmed PLC to allow for actuation on a timer or differential pressure basis and to handle upset conditions as would be the case if a screen has embedded particulate and thus not adequately reducing the differential pressure after a flushing sequence. The added complexity and cost associated with such controls is characteristic of our backwashing strainers which would provide the added benefit of cleaning the strainer screen and no just flushing collected debris.

So unless your application involves very low loads of hard materials such as pipe scale, automating the flush cycle is probably not practical.

Why not just use a Y strainer?

That actually might be the best approach, especially if the anticipated particle loading is low. As explained in our article SIMPLEX STRAINERS: Differences between Y and Basket Style Strainers, the advantage basket strainer provide is a higher straining ratio, thus you would be expected to flush less often.

Advantages of flushing strainers include:

Relative low cost and cost effective for small strainer sizes

Larger open area ratio than a Y-strainer equates to lower pressure drops across strainer and less frequent flushing

Quick delivery, usually within 2-4 weeks

There are times where the desired open area ratio (OAR) or particle sizes to be flushed require a custom fabricated design. Likewise other customizations such as nozzle orientation and centerline above the floor require a fabricated strainer. These often require 8-12 weeks of manufacturing lead time along with drawing approval prior to releasing to manufacturing.

The following PDF files can be opened in a new window or saved to your computer:

flushing strainer specifications