Benefits of Automation

DCF automated filtration systems are often used in lieu of

filter bag and cartridge systems to reduce operating costs.

The cost of replacement filter media and disposal of spent

media are pretty easy to calculate. Reduction of personnel's

interaction with the filtered liquid may reduce work related

injuries and frees-up those employees to do other tasks. The

aspects of liquid carry-out and process contamination are

also reduced. Carry-out refers to the process liquid lost

during the filter bag or cartridge change-out. During

change-outs there is increased risk for spillage and

contamination beyond the filter media. Many companies do not

fully appreciate costs associated with manually maintained

filtration systems!

Another advantage of a fully

automated system is maintaining a consistent downstream

pressure, eliminating the spikes in pressure characteristic

of manually maintained filtration systems; for some

applications steady pressure contributes product quality.

The DCF-Series was developed for non-water applications

for liquids that were especially challenging to filter due

to their viscosity, aggressiveness or viscoelastic

properties. An advantage of the DCF design is that it can

maintain a continuous low differential pressure while

minimizing product loss during its cleaning cycle. The DCF

design provides simple and reliable operation.

How

Mechanically Cleaned Filters Work

How

Mechanically Cleaned Filters Work

Liquid flows

into the top of the filter station and down through the

center of the filter element, passing through the element

walls and exiting the outlet connection. The topside of the

element is sealed; thus, all of the unfiltered liquid enters

the filter element. Whatever particles are too large to pass

thorough the element end-up falling to the bottom of the

vessel or become stuck against the inner circumference of

the element wall.

A

spring-loaded cleaning disc travels the length of the

element (the frequency of stroking is user programmable) and

this pushes any material stuck on the sides of the element

downwards to the bottom of the vessel, aptly referred to as

the "purge chamber". The quartered and spring-loaded

cleaning disc is designed to ensure even and consistent

force against the element to maximize cleaning efficiency

without damaging the 316SS element.

A

spring-loaded cleaning disc travels the length of the

element (the frequency of stroking is user programmable) and

this pushes any material stuck on the sides of the element

downwards to the bottom of the vessel, aptly referred to as

the "purge chamber". The quartered and spring-loaded

cleaning disc is designed to ensure even and consistent

force against the element to maximize cleaning efficiency

without damaging the 316SS element.

The specially

shaped purge chamber fills with a concentrate of solids and

is "flushed" based upon system pressure once the drain valve

is opened. The flushing force is the differential pressure

between the system pressure and atmospheric pressure. The

flushing frequency and duration are both user programmable

(and can be manual if desired), however the time required

for "flushing” is usually only a second or two.

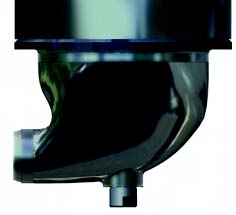

The

model illustrated to the left has twin actuators, a design

typically reserved for higher viscosity liquids. Less

viscous liquids often only require a single actuator.

DCF filter systems for 20 to 1500+ GPM cost ≥$11,000 to

$65,000+ depending upon the filter station body size and

automation required. The cleaning strokes require compressed

air and the frequency is adjustable by controlling the air

flow. Purging the filter chamber can be controlled manually,

although typically done via a "push button" controlled air

actuated ball valve. The automation of this system can

include pneumatic or electric timers for both stroke and

purge frequency or even preprogrammed PLC that can network

with the customers control system.

|

Specifications: |

|

|

• |

30-300 PSI operating pressure. |

|

• |

Flow rates up to 1,500 GPM. |

|

• |

Operating temperatures up to 400°F |

|

• |

Maximum solids concentration: 200 PPM |

|

• |

Particle retention range: 15 to 6250 microns |

|

• |

All wetted components 316SS |

|

• |

Elastomers and plastics are Viton®/EPT, urethane, Teflon® and Delrin® |

|

Requires: |

|

|

• |

5 CFM of 80 PSI clean, dry, non-lubricated compressed air. |

|

• |

115-230v/1ph/50-60Hz electrical service. |

Various models of DCF automated

filter systems are available depending upon the flow rate of

the application or special characteristics of the liquid

involved. DCF-400, DCF-800 and DCF-1600 have progressively

larger filter bodies to accommodate higher flow rates (20,

60 and 200 GPM maximum respectfully). Flow rates in excess

of 1500 GPM are addressed by connecting multiple DCF filter

systems to a common inlet, outlet and purge manifold and

customized PLC.

Specialized DCF Automated

Filter Systems

The DCF-2000 was designed for the

pulp and paper industry and filtration of "white water". It

differs from the other DCF designs because it has an

electrically operated motor driven cleaning disc, enabling

it to handle up to 72% solids at super fine 75-micron

retention. The cleaning disc not only continuously sweeps

the element clean to maintain a low differential pressure,

but also agitates the purge chamber to keep the solids in a

semi-liquid state for efficient purging.

DCF-FRY

OIL, is designed with FDA approved materials and insulation

to filter hot fry oil (up to 400F), eliminating vibratory

filters and paper band filters.DCF-3000 has dual cleaning

disc assemblies and has a capacity of about 2½ times the

DCF-1600. Depending upon the viscosity, the DCF-3000 can

handle from 500 to 1,500 GPM.

DCF-FRY

OIL, is designed with FDA approved materials and insulation

to filter hot fry oil (up to 400F), eliminating vibratory

filters and paper band filters.DCF-3000 has dual cleaning

disc assemblies and has a capacity of about 2½ times the

DCF-1600. Depending upon the viscosity, the DCF-3000 can

handle from 500 to 1,500 GPM.

Multiplexed

DCF Filtration SystemsThe DCF-1600, DCF-2000 and DCF-3000

can be "multiplexed" for higher capacities. We can

essentially mount multiple filter stations to a common

inlet, outlet and drain manifold to enable us to provide a

higher open area filtration ratio and handle higher flow

rates.

Multiplexed

DCF Filtration SystemsThe DCF-1600, DCF-2000 and DCF-3000

can be "multiplexed" for higher capacities. We can

essentially mount multiple filter stations to a common

inlet, outlet and drain manifold to enable us to provide a

higher open area filtration ratio and handle higher flow

rates.

Magnetically Actuated Cleaning

The model DCF-824 uses powerful rare earth magnetics to

drive the cleaning disc up and down, eliminating the need

for conventional actuators having physical linkage and seals

passing through the vessel. Thus, the MCF-824 is typically

used for hazardous liquids and locations where there is not

enough room to fit an external actuator.

The

functionality of the MCF-824 is the same as the other DCF

automatic filter systems with the difference being there is

a hollow shaft at the center of the system containing a

magnet which is coupled to an external magnet attached to

the cleaning disc. Pneumatic actuation from standard shop

compressed air injected through the base of the center

column pushes the internal magnet up and down. The outer

magnet within the cleaning disc follows the internal magnet.

The MCF-824 is used for flow rates up to 200 GPM and

liquids within 30-150 PSIG @ ≤180F. Its particle retention

range is from 150 to 6250 m.The

DCF-Series was developed for non-water applications where

the fluids being filtered were especially challenging, perhaps

being viscous, abrasive, or sticky. The advantages of the DCF

design is that it will maintain a continuous low differential

pressure and minimize product loss during the cleaning cycle.

The DCF design provides simple, reliable operation in which a

low initial investment is a key driving factor.

Use the navigation bar or click within the chart below to learn more about DCF, MCF and MCS filters and strainers.

|

|

|

| DCF-400 | DCF-800 | DCF-1600 |

| ≤ 20 GPM | ≤ 60 GPM | ≤ 200 GPM |

|

|

|

| DCF-2000 | MCF-824 | DCF-3000 |

| ≤ 200 GPM High Solids "white water" |

≤ 200 GPM Hazardous Fluids |

≤ 1500 GPM High Viscosity |

|

|

|

MCS-500 MCS-1500 |

MULTIPLEX |

| ≤ 1500 GPM | ≤ 12,000 GPM |

| FEATURES | BENEFITS |

| • Eliminate disposable filter media such | • Reduced disposal costs, material loss, labor, exposure and inventory |

| • Linear down and up cleaning motion | • Provides constant low differential pressure |

| • Uninterrupted product flow during cleaning | • Process consistency |

| • Compact footprint | • Retrofits to most existing pipelines |

| • For use with a wide range of contaminate types, including gels. | |