Eaton DCF-1600 self cleaning filtration systems, formerly known

as Ronningen-Petter DCF-1600, are designed for higher flow rates

and higher viscosity filtration applications. They are

constructed entirely of 316SS with 304SS mounting stand having

3" process connections and 2" purge port. DCF-1600 filters

are available with slotted wedge wire, perforated and defined

pore retentions ranging from 15 microns up to 1/4".

Eaton DCF-1600 self cleaning filtration systems, formerly known

as Ronningen-Petter DCF-1600, are designed for higher flow rates

and higher viscosity filtration applications. They are

constructed entirely of 316SS with 304SS mounting stand having

3" process connections and 2" purge port. DCF-1600 filters

are available with slotted wedge wire, perforated and defined

pore retentions ranging from 15 microns up to 1/4".

Design Operating Pressure: Standard unit pressure is 300 PSIG (20 bar), minimum 30 PSIG (2 bar). Units with Teflon® elastomers have a maximum pressure of 150 PSI (10 bar)

Filter Body Volume: 12.51 gallons = 47337.65 cm³

Purge Chamber Volume: 0.66 gallons = 2505.26 cm³ (Based on automatic purge)

Element Dimensions: 8” diameter X 24” long – 610 in²

Electrical Requirements: 110 or 220 Volt, 50/60 Hz cycle, 1 Phase (when applicable)

Air Requirements: 60 PSIG at 5 CFM – intermittent, must be clean, dry, and non- lubricated. ¼” NPTI process connection

Estimated Gross: 564 lbs (CCV/Push button purge)

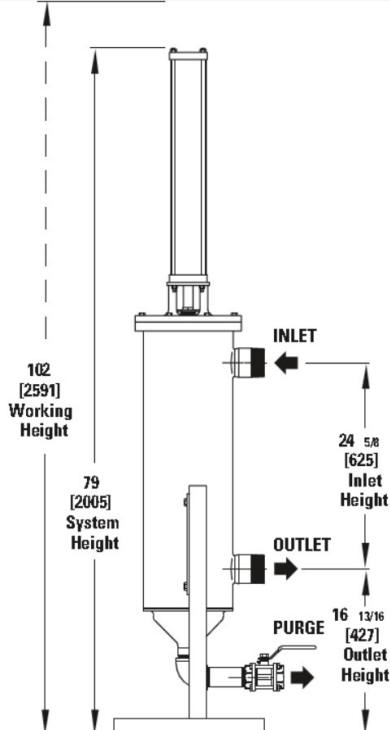

Dimensions: 36" x 48" x 90" for single actuator and 36” X 48” X 70” for twin actuator configurations

If you think you might have an application for a DCF-1600 filter system you can use our inquiry form to provide the design criteria or call us at 908.362.9981 so we can send you a proposal. Click on the following parts diagram or use the tables below to look-up the part numbers for specific DCF-1600 components, then send us a spare parts inquiry for a quick price and lead time.

| Filter Elements – Slotteddd | |

| Part Number | Description |

| 42631 | 15 Micron .0006” |

| 42632 | 25 Micron .001” |

| 40668 | 38 Micron .0015” |

| 42633 | 50 Micron .002” (325 Mesh) |

| 42634 | 75 Micron .003” (200 Mesh) |

| 45424 | 125 Micron .005” (120 Mesh) |

| 42636 | 150 Micron .006” (100 Mesh) |

| 47332 | 175 Micron .007” (80 Mesh) |

| 42652 | 200 Micron .008” (70 Mesh) |

| 42637 | 230 Micron .009” (60 Mesh) |

| 42638 | 380 Micron .015” (40 Mesh) |

| 47341 | 610 Micron .024” (30 Mesh) |

|

Filter Elements – Defined Pore (Other sizes are available-Consult Factory) |

|

| Part Number | Description |

| 63089 | 25 Micron |

| 63090 | 38 Micron |

| 63076 | 50 Micron |

| 63048 | 75 Micron |

| 63049 | 100 Micron |

| 63051 | 230 Micron |

| 63052 | 380 Micron |

| 63053 | 610 Micron |

| 63054 | 750 Micron |

| 63055 | 1125 Micron |

| Filter Elements – Perforated | |

| Part Number | Description |

| 42650 | 1550 Micron .0625” |

| 47330 | 3125 Micron .125” |

| 42661 | 6250 Micron .250” |

|

Actuator Components and Misc. Kits (Single Actuator Style) |

|

| Part Number | Description |

| 40652 | 4” Actuator – Viton® –

(Current) (use to be 46683) |

| 40653* | 4” Actuator Repair Kit –

Viton® – (Current) for Actuator 40652 |

| 46685** | 4” Actuator Repair Kit –

Viton® – (Previous) for Actuator 46404 |

| 42750 | 4” Actuator – Rod and Piston

for Actuator 40652 |

| 46682 | 4” Actuator Repair Kit– Buna N

(Previous) for Actuator 46688 |

| P-20763-BRZ | Elbow, 3/8” NPTE 45° Flare 90 Degrees |

| 46412 | Screw, 3/8”-16 X ¾” Flat Hd. |

| P-10694-SS4 | Nut, 3/8”-16 Locking w/Nylon |

| 46405 | Plate, Mtg. Actuator |

| 46599 | 5” Actuator – Viton® |

| 46600 | 5” Actuator Repair Kit

(Viton®) for Actuator 46599 |

| 42753 | 5” Actuator – Rod and Piston

for Actuator 46599 |

| P-20763-BRZ | Elbow, 3/8” NPTE 45° Flare 90 Degrees |

| 47502 | Aluminum Actuator (Each) for 47501 |

| 47514 | Actuator Seal Repair Kit (BUN) – ALU or SS |

| 47503 | Center Shaft |

| 47515 | Safety Switch (Aluminum) |

| 47522 | Safety Switch (SS) |

| P-35127-SS6 | Washer, Locking 3/8” |

| 47510 | Screw, 3/8”-16 X 1-1/2” Hex. Hd. (316SS) |

| P-21713-BRZ | Adapter, 3/8” NPTE X 45° |

| 42909 | DCF Lid for Adjustable Packing |

| 42904 | Star Wheel, Packing Adjuster |

| 42961 | Adj. Packing Retrofit Kit – Urethane |

| 42958 | Adj. Packing Repair Kit – Urethane |

| 42924 | Adj. Packing Retrofit Kit – Teflon® |

| 42919 | -Adj. Packing Repair Kit – Teflon® |

| 45492 | Adj. Packing Retrofit Kit – Viton® |

| 45498 | -Adj. Packing Repair Kit – Z-Seal Viton® |

| RPS0000014 | Adj. Packing Repair Kit - Viton/Gylon |

| P-10336-BRZ | Plug, Pipe ¾” Sq. Hd. |

| 42630 | Screw, Lid Hold Down, 7/16”-14 X 1-1/4” lg. Hex Hd |

|

Lid Components – Packing Shaft Seal – Previous – Serial No. 1726 and lower |

|

| Part Number | Description |

| 40647 | Lid Assembly for Cartridge Assembly |

| 42411 | Cartridge Assembly Complete –

Bronze -Viton® seals |

| 42441 | Cartridge Assembly Complete –

Bronze -Teflon® seals |

| 42409 | Cartridge Only Less Seals |

|

Cartridge Repair Kit (Consists of Inner and Outer O-Rings, Backup/Retainer Ring, Wiper/Scraper/Retainer Rod and Screws) |

|

| 46683 | Cartridge Repair Kit, Bronze Viton® Seals |

| 46693 | Cartridge Repair Kit, Bronze Teflon® Seals |

| Fluid Seal and Components** | |

| 45410 | Fluid Seal Assembly Less Seals (See Below) |

| 45406 | Urethane Seals for Fluid Seal |

| 45407 | Teflon® Seals for Fluid Seal |

| 47455 | Fluid Seal Lantern Ring |

| RPS0000037 | Viton/Gylon Seals for Fluid Seal |

| RPS0000038 | Viton Seals for Fluid Seal |

| 45411 | Flush Kit for Fluid Seal |

|

Cleaning Disc Assembly – Consists of disc, plates, adapter, spacers, spring and screws |

|

| 40632 | Wide Edge UHMWPE 180° F Yellow |

| 40633 | Wide Edge Kynar 285° F (Off White) |

| 40634 | Wide Edge **Teflon® 400° F (White) |

| 45483 | Wide Edge **Teflon® (Soft

Spring) 400° F (White) |

| 47141 | Wide Edge Nylon 275° F (Transparent White) |

| 40703 | Wide Edge Urethane (Soft

Spring) 175° F (Green) |

|

Cleaning Disc Repair Kit – Consists of disc, spring, and screws |

|

| 31338 | Wide Edge UHMWPE 180° F (Yellow) |

| 47308 | Wide Edge ** Teflon® 400° F (White) |

| 47307 | Wide Edge Kynar 285° F (Off White) |

| 40712 | Wide Edge Nylon 275° F (Transparent White) |

| 40707 | Wide Edge Urethane (Soft

Spring) ** 175° F (Green) |

| Cleaning Disc Kit – Replacement Partss | |

| Part Number | Description |

| 40629 | Adapter |

| P-30886-SS6 | Screw, ¼”-20 X 2” lg. Hex Hd. |

| P-41289-SS6 | Nut, ¼”-20 Self Locking |

| P-31303 | Top Cleaning Disc Plate |

| P-31304 | Bottom Cleaning Disc Plate |

| P-31308 | Spacer (4-Required) |

| P-31307 | Disc Spring (Standard) |

| 47011 | Disc Spring (Soft) – Used with defined pore elements only |

| P-10767-SS6 | Screw – 5/16”-18 X 5/8” lg. Hex Hd. |

| 31328 | Pliers, Assembly Tool |

| Compressor Assembly | |

| 40626 | Compressor Assy. (316SS) –

Four Compressor Bars and a Ring Lid O-Rings |

| 42622 | Viton® -400° F |

| 42623 | EPT (Nordel) -300° F |

| 42624 | Teflon® -400° F |

| 42621 | Buna-N -220° F |

| 45421 | White Nitrile (Food Grade) -270° F |

| Element O-Ring (Upper and Lower Required) | |

| 42627 | EPT (Nordel) – 300° F |

| 42626 | Viton® -400° F |

| 42628 | Teflon® -400° F |

| 42625 | Buna-N – 220° F |

| 45422 | White Nitrile (Food Grade) – 270° F |

| DCF1600 Body Assembly | |

| 40611 | Body Assembly – Same Side In/Out – 3” NPTE |

| 40612 | Body Assembly – Opposite Side In/Out – 3” NPTE |

| 47162 | Body Assembly – Same Side In/Out – 3” ANSI Flange |

| 47164 | Body Assembly – Opposite Side In/Out – 3” ANSI Flange |

| 47163 | Body Assembly – Same Side In/Out – 3” DIN Flange |

| 47165 | Body Assembly – Opposite Side In/Out – 3” DIN Flange |

| 47192 | Stealth Body Assembly – Same Side In/Out – 3” NPTE |

| 47193 | Stealth Body Assembly –

Opposite Side In/Out – 3” NPTE |

| 47194 | Stealth Body Assembly – Same Side In/Out – 3” ANSI Flange |

| 47195 | Stealth Body Assembly –

Opposite Side In/Out – 3” ANSI Flange |

| 47189 | Stealth Body Assembly – Same Side In/Out – 3” DIN Flange |

| 47190 | Stealth Body Assembly –

Opposite Side In/Out – 3” DIN Flange |

| Purge Valve – Current -April 2013 to Present | |

| Part Number | Description |

| RPV0000020 | 2" Ball Valve Complete

(Flo-Tite) 2-way, Full Port, 2 pc, Threaded. |

| KIV0000006 | Ball Valve Repair Kit For RPV0000020 |

| KIR000029 | Mounting Kit, Purge Valve Actuator 45475 |

| 45475 | Actuator, Rotary, Jamesbury |

|

Purge Valve – Serial No. 1226 and Higher Through March 2013 |

|

| 41009 | 2” Ball Valve Complete

(Parker) 2-Way, Full Port, 3 Pc., Threaded |

| 41006 | Ball Valve Repair Kit for 41003 |

| 41003 | 2” Ball Valve (Parker) Body Only |

| 47421 | Adapter, Rotary Purge Actuator |

| 47420 | Mounting Bracket – 2” Valve to Actuator |

| P-10767-SS6 | Screw, 5/16”-18 X 5/8” Hex Hd. Cap |

| P-20669-SS4 | Washer, 5/16” Heavy Split |

| 45475 * | Rotary Actuator, Jamesbury |

| 60179 | Rotary Actuator 45475 Repair Kit |

| P-42312 | Screw, M8 X 1.25 |

| Purge Valve – Previous – Serial No. 1225 and Lower | |

| P-22950-SS6 | Purge Valve -2-Way Threaded |

| P-12447 | Purge Valve Repair Kit for P-22950-SS6 |

| P-21075 | Actuator Repair Kit for P-41551 |

| 40673 | Continuous Clean Valve (CCV) |

| 40661 | Continuous Clean Valve (Design Retired – Use 40673) |

| 45545 | Valve, Air, 4-Way with Push Button |

| 42751 | Pneumatic Timer (Stroke) |

| 42752 | Pneumatic Timer (Purge) |

| 46855 | Electric Timer, Repeat Cycle 100-240VAC |

| 46858 | Solenoid Valve, 4-Way 110VAC

(Single valve – 2-Required) |

| 46853 | Solenoid Valve, 4-Way 220VAC

(Single valve – 2-Required) |

| 45667 | -Repair Kit for Solenoid

Valves 46858 & 46853 |

| 46857 | Circuit Breaker, 2-Pole, 1.6 AMP |

| P-10937-BRZ | Muffler, ¼” NPTE |

| 46856 | Timer Base |

| Automation – Previous – Before September 1997 | |

| 45557 | Solenoid Valve, 4-Way 24VDC

(Single valve – 2-Required) |

| 45667 | Repair Kit for Solenoid Valve 45557 |

| 45817 | Power Supply, 85/264V-24V, 10 W |

| 45674 | Fuse, 1.6 AMP |

| 45978 | Timer, 1-10 Sec. Dual

Flip-Flop Repeat – Purge |

| 45668 | Timer, 5-50 Sec. Dual

Flip-Flop Repeat – Stroke |

| P-30488-ALU | Muffler, ¼” NPTE (Shell Type) |

| Pressure Gauges | |

| P-20275-BRZ | Gauge, 2-1/2”, 200 PSI, Liquid

Filled, Back Conn., Bronze |

| P-20275-SS6 | Gauge, 2-1/2”, 200 PSI, Liquid

Filled, Back Conn., Stainless Steel |

| Siemens PLC Components | |

| Part Number | Description |

| 54002 | EEPROM, Siemens S7-200 |

| *PLC REPLACEMENT | PLC, Siemens S7-200 AC/AC/AC |

| *PLC REPLACEMENT | PLC, Siemens S7-200 DC/DC/DC |

| 54006 | Siemens Operations Manual |

| 54007 | Siemens Display Module |

| 54003 | Expander Module, Siemens S7-200 |

| 46991 | Battery Cartridge S7-200 |

| Allen-Bradley PLC Components | |

| *PLC REPLACEMENT | PLC, MicroLogix 1200 |

| special order | Display, PanelView 300 |

| 81528 | Relay Output Module |

| 81521 | Cable, PLC to Display |

|

Misc. Automation Components Common to Either PLC |

|

| 46984 | Power Supply, 110VAC/24VDC 2.5 amp |

| 54001 | Power Supply, 220VAC/24VDC 2.5 amp |

| P-11075-BRZ | Differential Pressure Switch |

| P-20992 | Pressure Transmitter, 1:1 Repeater (PMC) each |

| 45557 | Solenoid Valve, 4-Way, 24VDC |

| 45667 | Repair Kit for P-41334 |

| P-12511 | Bulb, 32 V |

| 49001 | 2.5 AMP Fuse |