Automatic

backwashing strainers are a cost-effective alternative to duplex

strainers for high flow rate applications where removal and cleaning

of large/heavy strainer baskets would be difficult. Automatic

backwashing strainers are also used for remote locations having

limited personnel available to service simplex and duplex basket

strainers.

Automatic

backwashing strainers are a cost-effective alternative to duplex

strainers for high flow rate applications where removal and cleaning

of large/heavy strainer baskets would be difficult. Automatic

backwashing strainers are also used for remote locations having

limited personnel available to service simplex and duplex basket

strainers.

Application Considerations

Automatic backwashing strainers use about 5% of the liquid filtered during the backwashing process, which can last several minutes, thus they are typically used for water filtration applications although can be used for any liquid not considered scarce or expensive.

Automatic backwashing strainers are designed to operate within a specific pressure range, ≥30 PSIG and ≤285 PSIG.

Typical applications include:

Water treatment: Automatic backwashing strainers are used in water treatment plants to remove impurities from raw water sources, such as rivers and lakes, before the water is treated and used for industrial or agricultural applications such as irrigation.

Industrial process water: Automatic backwashing strainers are used in industrial processes that require large quantities of clean water, such as power generation, chemical manufacturing, primary metals manufacturing and food and beverage production. Such facilities use water for cleaning and cooling processes.

Fire protection systems: Automatic backwashing strainers are used to remove debris and sediment from the water used in fire protection systems, such as fire sprinklers and standpipes, to ensure that the system is able to function properly in case of emergency.

Although we can supply automatic strainers with mesh lined elements for retentions as fine as 75 microns, they are best suited for coarse retentions in the ¼" range and perhaps as fine as 100 mesh (150 microns). Due to the volume of process liquid used for cleaning, automatic backwashing strainers are almost exclusively used for water filtration; our standard materials of construction include cast iron, carbon steel and 316SS and, for warm sea water applications, an alloy like Hastelloy is used.

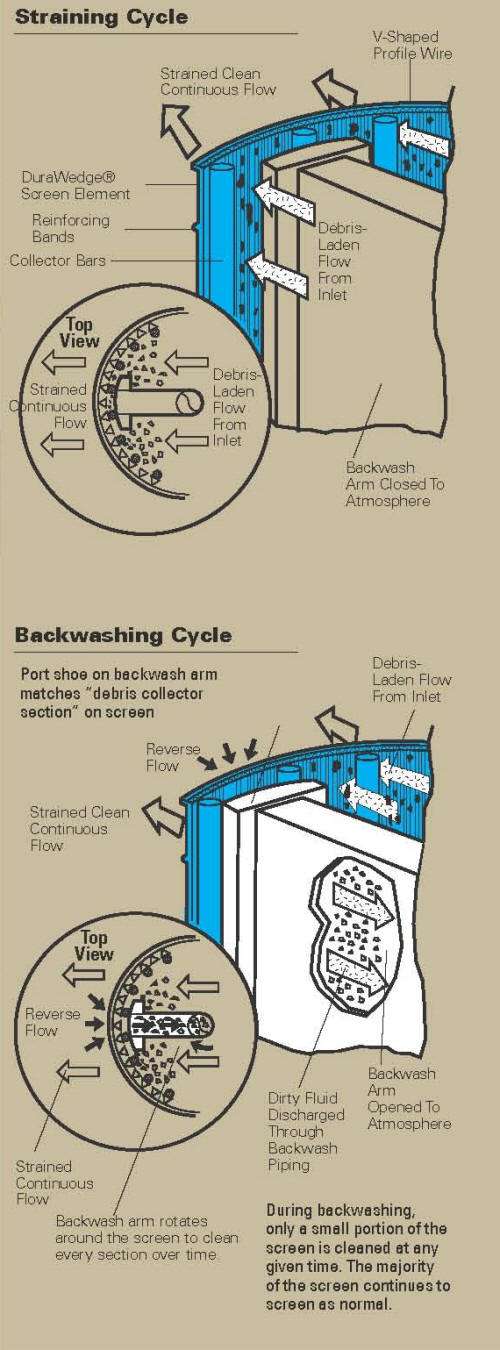

Filtration Mode

Flow enters the strainer body and must flow upwards into the strainer element, passing through geometry which evenly distributes the flow across the inner circumference of the filter element. The water passes though the perforated or mesh lined element, exiting the vessel through the outlet nozzle. The element is stationery and particulate that cannot pass through the element either falls to the bottom of the vessel or is held against the surface of the element due to the systems differential pressure.

Backwash Mode

The backwashing cycle is actuated either by manual override, differential pressure or programmable timer. Once it begins, simultaneously a draining valve opens and a motor atop of the strainer begins rotating a hollow shaft within the portion of the strainer that contains the filter element. Attached to this hollow shaft is a vacuum nozzle which extends to just above the inner surface of the filter element.

As this nozzle sweeps around the interior circumference of the filter element the resulting differential pressure (system pressure vs. atmospheric pressure) causes the clean, filtered liquid to reverse flow through that section of the element, dislodging any material stuck to the inner surface of the element, and it is vacuumed through the hollow nozzle shaft, exiting the system via the backwash valve and drain.

The motor has sufficient torque, and the nozzle arm is robustly designed, to break-up debris such as sticks and other organic material that might get stuck within the filter element.

Maintenance

Periodically it might be necessary to open the strainer body and remove large debris that accumulates at the bottom of the strainer. The straining element and backwash nozzle assembly are attached to the top section of the strainer, so it can be easily lifted for strainer element inspection and cleaning-out the bottom as needed. It is also possible to install a manway in the body to facilitate inspections and clean-out without having to disassemble the strainer.

Automatic Strainer Control Systems

Automatic strainers require a control package and there are three basic versions, each of which can be further customized for all stainless-steel wetted parts, explosion-proof components and optional control methods.

ACS-1 Control Package (base package):NEMA 4 panel box with adjustable timer, differential pressure override, 10 Amp control relay for backwash valve activation, "Power On”, “Backwash Cycle On”, “High Differential Pressure” indicator lights, selector switch to manually control the backwash valve and contact terminals for motor starter and external alarm. 120 Volt, 1 Phase, 60 Hz motor. A single element differential pressure switch having aluminum wetted components activates the cleaning cycle. Dual element switches are available as an option to activate an additional alarm signal.

2” through 16” strainers, have electrically actuated standard port ball valves with a brass body, 316 SS ball & stem, TF seats/seals and threaded connections. 18” through 24” strainers have flanged valves with a carbon steel body, ball & stem and TFE seats & seals. Electric actuators are NEMA 4 watertight enclosures operated from a signal from the control panel. Pneumatically actuated valves with NEMA 4 pilot solenoid are also available.

The ACS-2 Control Package includes a motor starter in the NEMA 4 panel box in addition to the ACS-1 control package.

ACS-3 Control Package is for 460 Volt, 3 Phase, 60 Hz motors, includes a control voltage transformer and a motor starter in the NEMA 4 panel box in addition to the standard features of the ACS-1 package.

AUTOMATIC STRAINER

FEATURES:

• Designed and constructed in accordance with ASME

Section VIII, Division 1.

• ASME Code Stamp is available.

• Seismic qualification is also available.

• Unique quad shaft seal ensures that no process media

leaks down the sides of the strainer.

• The motor, gear reducer, cover, and complete

internal operating mechanism lift off as a unit, making

all components easily accessible.

• Only a small portion of system flow (about 5%) is used during

backwash due to the efficient hydraulic design.

• Zero Bypass of Contaminants because element caps are

epoxy sealed to screen media.

• The cover O-ring permits

resealing without time-consuming gasket replacements and

adjustment.

• Manual override is a standard feature.

There are many variations and options that we do not show

online, please fill-out our

self cleaning strainer inquiry form

for assistance, we typically reply the same day or

within 24 hours.