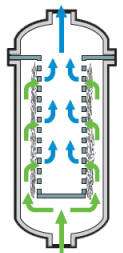

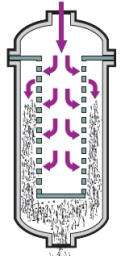

During filtering mode, flow enters the bottom of the filter station, passing through the filter element wall and through the outlet of the vessel. Particulate too large to pass through the element either falls to the bottom of the filter vessel or is sucked against the side of the element.

During backwashing mode a 3-way valve cycles, closing the inlet for a few seconds and opening to the drain port, thus the system pressure reverses flow through the element; the filtered fluid passes through the element dislodging accumulated particulate from the filter element openings and they flushed out through the drain port.

Single filter stations can be controlled manually or

automated. Multiple station systems typically use

automated

valves

and once backwashing mode begins, each filter station

undergoes the backwashing process until all have been

backwashed.

Single filter stations can be controlled manually or

automated. Multiple station systems typically use

automated

valves

and once backwashing mode begins, each filter station

undergoes the backwashing process until all have been

backwashed.

Backwashing is initiated either via manual override,

programmable timer or differential pressure. The

system needs to be sized such that there's sufficient

filtration area available during backwashing and the process

flow needs to accommodate not only the flow required for the

process but the slightly additional flow required for

backwashing. If the system consists of only a few

filter stations the backwash volume and time is negligible

but it might be a consideration for larger systems.

| INTERNAL | EXTERNAL | ||

| • | Low Viscosity | • | Viscous Liquids |

| • | Low Value | • | High Value |

| • | >45 PSI | • | <45 PSI |

| • | Fluctuations are okay | • | Fluctuations are not okay |

Features:

• Smooth pipe transitions minimize pressure drop.

• Many backwash options to support

operator-free service.

• < 2% of system volume required for

backwashing.

• Quick coupler valve connectors simplify body tube

removal.

Options:

• Single, double and multiplex configurations to

handle high flow rates.

• Internal and external backwashing configurations.

Limitations:

• 100 to 150 ppm particle concentration.

• 12 FPS flow velocity.

For backwashing:

• Requires 45 PSI for internal backwashing.

• Clean backwash source for external backwashing.

• Some fabric covered elements require backwashing pressure <50 PSI.

What is the Maximum Flow per Element?

| 1. | Flow rate in GPM (gallons per minute) |

| 2. | The retention size required |

| 3. | Viscosity of the fluid |

| 4. | Is it a continuous or batch application? |

These characteristics and others are included on our online inquiry form, please fill it out as much as applicable so that we can begin to assist you with the proper selection and sizing of a filter system.

Approximate sizing chart

| Maximum Flow Rate | Model | Type |

| 60 GPM | 1100S | Simplex |

| 1100D | Duplex | |

| 480 GPM | 1100-IB | Internal Backwashing |

| 1100-EB | External Backwashing | |

| 150 GPM | 1500S | Simplex |

| 1500D | Duplex | |

| 450 GPM | 2200S | Simplex |

| 2200D | Duplex | |

| 3,500 GPM | 2200-IB | Internal Backwashing |

| 2200-EB | External Backwashing | |

| 5,880 GPM | 3300S | Simplex |

| 3300D | Duplex | |

| 3300-IB | Internal Backwashing |