The

DCF-800 automatic filter has a volumetric capacity of 4

gallons and provides a gross filtration area of 264

in2 using a single 7" diameter x 12" long

filter element. The Eaton DCF-800 design was acquired

by Ronningen-Petter during their 2006 acquisition of their

filtration products. Sometimes referred to as a

"scraper strainer", the DCF-800 is a type of automatic

filter to provide retentions from as fine as 15 microns as

course as 1/4".

The

DCF-800 automatic filter has a volumetric capacity of 4

gallons and provides a gross filtration area of 264

in2 using a single 7" diameter x 12" long

filter element. The Eaton DCF-800 design was acquired

by Ronningen-Petter during their 2006 acquisition of their

filtration products. Sometimes referred to as a

"scraper strainer", the DCF-800 is a type of automatic

filter to provide retentions from as fine as 15 microns as

course as 1/4".

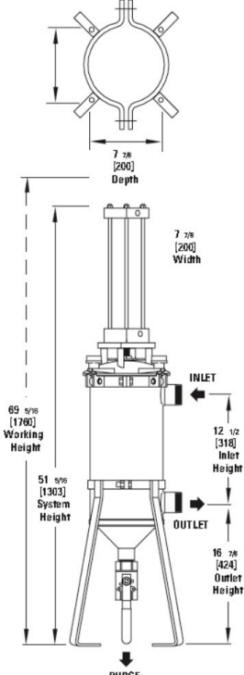

Design Operating Pressure: Standard unit pressure is 300 PSIG (20 bar), minimum 30 PSIG (2 bar). Units with Teflon® elastomers have a maximum pressure of 150 PSI (10 bar)

Filter Body Volume: 4.19 gallons = 15871.56 cm³

Purge Chamber Volume: 0.24 gallons = 823.54 cm³ (Based on automatic purge)

Element Dimensions: 7” diameter X 12” long – 264 in²

Electrical Requirements: 110 or 220 Volt, 50/60 Hz cycle, 1 Phase (when applicable)

Air Requirements: 60 PSIG at 5 CFM – intermittent, must be clean, dry, and non- lubricated. ¼” NPTI process connection

Estimated Gross: 100 lbs (CCV/Push button purge). 231 lbs. with control enclosure on stand

Dimensions: 17" x 16" x 54" single station only (CCV/push button). All other configurations are 36” X 36” X 54”

| Slotted Elements | |

| Part Number | Description |

| 46661 | 15-Microns (0.0006”) |

| 46662 | 25-Microns (0.001”) |

| 40665 | 38-Microns (0.0015”) |

| 46663 | 50-Microns (0.002”) |

| 46664 | 75-Microns (0.003”) |

| 46665 | 100-Microns (0.004”) |

| 46666 | 150-Microns (0.006”) |

| 46657 | 175-Microns (0.007”) |

| 46656 | 200-Microns (0.008”) |

| 46667 | 230-Microns (0.009”) |

| 46668 | 380-Microns (0.015”) |

| 47340 | 610-Microns (0.024”) |

| 46659 | 750-Microns (0.030”) |

| 46658 | 1125-Microns (0.045”) |

| Perforated Elements | |

| 42674 | 1550-Micron (0.062”) |

| 42675 | 3125=Micron (0.125”) |

| 42676 | 6250-Micron (0.250”) |

| Defined Pore Elements | |

| 63087 | 25-Microns (0.001”) |

| 63088 | 38-Microns (0.0015”) |

| 63077 | 50-Microns (0.002”) |

| 63060 | 75-Microns (0.003”) |

| 63061 | 100-Microns (0.004”) |

| 63062 | 150-Microns (0.006”) |

| 63063 | 230-Microns (0.009”) |

| 63064 | 380-Microns (0.015”) |

| 63065 | 610-Microns (0.024”) |

| 63066 | 750-Microns (0.030”) |

| 63067 | 1125-Microns (0.045”) |

| 45694 | O-ring, Element – Defined Pore Only -Teflon® |

| Body Assembly (Teflon® Element Seals) | |

| Part Number | Description |

| 45451 | Body Assembly, 2” NPTE

Inlet/Outlet, 1½” NPTI Purge |

| P-43853-CST | Screw, ½”-13 X 1 ½” Hex Hd. |

| P-30672-CST | Leg Assembly, Half (Carbon Steel) |

| P-10859-CST | Nut, ½”-13 X 5/16” Thk. Hex Jam |

| 45661 | Actuator, Rotary, R/P 200 lb/in @ 60 PSI |

| 45663 | Actuator Repair Kit |

| P-20760-BRZ | Adapter, ¼” NPT X 45° Flare |

| 45675 | Linkage Kit, Actuator to Purge Valve |

| 45657 | Purge Valve, 2-Way 1 ½” NPTI |

| 45658 | Kit, Repair, Purge Valve |

| P-41181-TEV | Lid O-ring – Teflon |

| 45694 | O-Ring, element DCF TFV |

| Single Actuator Components | |

| 45460 | Lid for Teflon® Design

– Single Actuator Assembly |

| 42630 | Screw, 7/16”-14 X 1¼” Hex. Hd. |

| 45463 | Standoff |

| 45444 | Compressor Bar |

| 45925 | Screw, 5/16”-18 X ¾” lg. Soc Set |

| 45458 | Extension |

| P-10339-SS6 | Plug, Pipe |

| 45592 | Nut, ½-13 Flex Loc |

| P-30848-SS4 | Screw, ½-13 X 1 ¼” Hex Hd. Cap |

| Cleaning Disc Repair Kits* | |

| 46680 | Kit, Cleaning Disc Repair – Teflon® |

| 46681 | Kit, Cleaning Disc Repair – Kynar |

| 45542 | Spacers, Cleaning Disc |

| 42925 | Adapter, Cleaning Disc to Actuator |

| 45539 | Plates, Cleaning Disc |

| Cleaning Disc Assembly** | |

| 46742 | Teflon® Disc |

| 46743 | Kynar Disc |

| Cleaning Disc Repair Kits | |

| Part Number | Description |

| 46744 | Kit, Cleaning Disc Repair – UHMWPE |

| 46680 | * Kit, Cleaning Disc Repair – Teflon® |

| 46681 | Kit, Cleaning Disc Repair – Kynar |

| 40706 | Kit, Cleaning Disc

Repair – Urethane (f/Defined Pore) |

| 45542 | Spacer, Disc |

| 42925 | Adapter, Disc |

| 45539 | Plate, Cleaning Disc |

| P-10807-SS4 | Washer, 5/16” Flat |

| P-10771-SS6 | Screw, 5/16”-18 X 1” Lg. Hex Hd. Cap |

| Cleaning Disc Assembly | |

| 46741 | UHMWPE Disc Ass’y |

| 46742 | Teflon® Disc Ass’y |

| 46743 | Kynar Disc Ass’y |

| 46608 | Urethane Disc Ass’y |

| Single Actuator Components | |

| 46690 | Actuator, 3¼” X 11½” – Viton® Single |

| 46724 | Actuator Repair Kit |

| 63068 | O-ring, Comp. Assembly – Defined Pore Element |

| P-20763-BRZ | Elbow, 3/8” NPTE X 45° Flare |

| 46217 | Element Puller |

| 42903 | Adjustable Packing Wheel |

|

Cleaning Disc Repair Kits consist of Cleaning Disc, Spring, Screws and Nuts. |

|

|

* Kit includes both standard spring for std.

element and soft spring for defined pore elements. |

|

| Lid Packing – Single Actuator | |

| 42957 | Packing, Urethane |

| 42956 | Packing, Teflon® -Current |

| 42918 | Packing, Teflon®

-Previous 1862 and lower (7/8” Gland) |

| 45491 | Packing, Viton® 2 seal (each – 2 required) |

| 47559 | Lid (Twin Actuator Design) |

| 47180 | Screw, 5/16”-18 X 1” Lg. Socket Set |

| 47560 | Extension Pins – Lid to Single Actuator |

| Fluid Seal Components | |

| 45406 | Kit, Packing Fluid

Seal – Urethane – Upper & Lower Seal (Twin Actuator Design) |

| 45407 | Kit, Packing Fluid

Seal – Teflon – Upper & Lower Seal (Twin Actuator Design) |

| 47459 | Fluid Seal (2 Piece) – (Star Wheel & Lantern) |

| 45410 | Fluid Seal Retrofit Kit ** |

| 45411 | Fluid Seal Flush Kit *** |

| 47455 | Ring, Lantern (1-7/8” Lg.) |

| Twin Actuator Components | |

| Part Number | Description |

| 47568 | Twin Actuator Assembly

(Wetted Parts 316SS)* |

| 47569 | Twin Actuator Assembly (All Parts 316SS) |

| 47553 | Actuator – Twin Design

(Wetted parts 316 SS) |

| 47554 | Actuator Rebuild Kit –

Buna-N (One Actuator Only) |

| 47552 | Center Shaft – Twin Actuator Design |

| 42848 | Screw, 5/16”-18 X 1¼” Lg. Hex. Hd. |

| P-20762-BRZ | Elbow, ¼” NPTE X 45° Flare 90° |

| Adjustable Packing Components | |

| 42958 | Packing, Urethane |

| 42919 | Packing, Teflon® |

| 45490 | Packing, Viton® Z-Seal |

| Slotted Elements | |

| Part Number | Description |

| 46661 | 15-Microns (0.0006”) |

| 46662 | 25-Microns (0.001”) |

| 40665 | 38-Microns (0.0015”) |

| 46663 | 50-Microns (0.002”) |

| 46664 | 75-Microns (0.003”) |

| 46665 | 100-Microns (0.004”) |

| 46666 | 150-Microns (0.006”) |

| 46657 | 175-Microns (0.007”) |

| 46656 | 200-Microns (0.008”) |

| 46667 | 230-Microns (0.009”) |

| 46668 | 380-Microns (0.015”) |

| 47340 | 610-Microns (0.024”) |

| 46659 | 750-Microns (0.030”) |

| 46658 | 1125-Microns (0.045”) |

| Perforated Elements | |

| 42674 | 1550-Micron (0.062”) |

| 42675 | 3125=Micron (0.125”) |

| 42676 | 6250-Micron (0.250”) |

| Defined Pore Elements | |

| 63087 | 25-Microns (0.001”) |

| 63088 | 38-Microns (0.0015”) |

| 63077 | 50-Microns (0.002”) |

| 63060 | 75-Microns (0.003”) |

| 63061 | 100-Microns (0.004”) |

| 63062 | 150-Microns (0.006”) |

| 63063 | 230-Microns (0.009”) |

| 63064 | 380-Microns (0.015”) |

| 63065 | 610-Microns (0.024”) |

| 63066 | 750-Microns (0.030”) |

| 63067 | 1125-Microns (0.045”) |

| 45694 | O-ring, Element – Defined Pore Only -Teflon® |

| Body Assembly (Teflon® Element Seals) | |

| Part Number | Description |

| 45451 | Body Assembly, 2” NPTE Inlet/Outlet, 1½” NPTI Purge |

| P-43853-CST | Screw, ½”-13 X 1 ½” Hex Hd. |

| P-30672-CST | Leg Assembly, Half (Carbon Steel) |

| P-10859-CST | Nut, ½”-13 X 5/16” Thk. Hex Jam |

| 45661 | Actuator, Rotary, R/P 200 lb/in @ 60 PSI |

| 45663 | Actuator Repair Kit |

| P-20760-BRZ | Adapter, ¼” NPT X 45° Flare |

| 45675 | Linkage Kit, Actuator to Purge Valve |

| 45657 | Purge Valve, 2-Way 1 ½” NPTI |

| 45658 | Kit, Repair, Purge Valve |

| P-41181-TEV | Lid O-ring – Teflon |

| 45694 | O-Ring, element DCF TFV |

| Single Actuator Components | |

| 45460 | Lid for Teflon® Design

– Single Actuator Assembly |

| 42630 | Screw, 7/16”-14 X 1¼” Hex. Hd. |

| 45463 | Standoff |

| 45444 | Compressor Bar |

| 45925 | Screw, 5/16”-18 X ¾” lg. Soc Set |

| 45458 | Extension |

| P-10339-SS6 | Plug, Pipe |

| 45592 | Nut, ½-13 Flex Loc |

| P-30848-SS4 | Screw, ½-13 X 1 ¼” Hex Hd. Cap |

| Cleaning Disc Repair Kits* | |

| 46680 | Kit, Cleaning Disc Repair – Teflon® |

| 46681 | Kit, Cleaning Disc Repair – Kynar |

| 45542 | Spacers, Cleaning Disc |

| 42925 | Adapter, Cleaning Disc to Actuator |

| 45539 | Plates, Cleaning Disc |

| Cleaning Disc Assembly** | |

| 46742 | Teflon® Disc |

| 46743 | Kynar Disc |

|

Body Assembly (Teflon® Element Seals)

T1:U23Element Components |

|

| Part Number | Description |

| 63078 | Screw, #10-24 ¼” X 1” lg. Shoulder Screw |

| 63068 | Ring, Element Seal

Retainer – Defined Pore Element |

| 46653 | Screw, #10-24 X ½” Hex. Hd. |

| 45968 | Ring, Element Seal

Retainer – Slotted & Perforated Element |

| 46646 | O-ring, Upper Element

Seal – Slotted & Perforated Element |

| 46217 | Element Puller |

| Single Actuator Components (Current) | |

| 46690 | Actuator, 3¼” Bore X 11½” Stroke (Single) |

| 46724 | Actuator 46690 Repair Kit |

| 45457 | Bolt, 5/16”-18 X 2¾” (Single Actuator) |

| P-12375-SS6 | Washer, 5/16” Locking |

| 47574 | Washer, 5/16” SAE Flat |

| P-20763-BRZ | Elbow, 3/8” NPTE X 45° Flare |

| 42903 | Wheel, Packing – Single Actuator |

| 45491 | Packing, Lid Viton® Z-Seal |

| 42956 | Packing, Teflon® |

| Twin Actuator Components (Current) | |

| 45443 | Lid for Twin Actuators

with Adjustable Packing & Fluid Seal |

| 45445 | Standoff – Adjustable Packing Design |

| 47568 | Twin Actuator Assembly

(Wetted Parts 316 SS) |

| 47569 | Twin Actuator Assembly (All Parts 316 SS) |

| 47553 | Twin Actuator – Single

Act. Only (Wetted parts 316 SS) |

| 47571 | Twin Actuator – Single

Act. Only (All parts 316 SS) |

| 47554 | Actuator Rebuild Kit –

Buna-N (One Actuator Only) |

| 47552 | Center Shaft – Twin Actuator Design |

| 45455 | Bolt, 5/16”-18 X 4” SS4 |

| P-20762-BRZ | Elbow, ¼” NPTE X 45° Flare |

| 42904 | Wheel, Adjustable Lid Packing |

| 45407 | Packing, Adjustable Teflon® |

| 45490 | Packing, Adjustable Viton® Z-Seal |

| 45456 | Standoff – Fluid Seal Design |

| 45461 | Bolt, 5/16”-18 X 5” Lg. – Fluid Seal Design |

| 47459 | Fluid Seal Assembly

(Star Wheel & Lantern Ring) |

| 47455 | Ring, Lantern (New – 1-7/8” Lg.) |

| 45407 | Seal, Teflon®, Twin

with Fluid Seal (Upper & Lower) |

| Automation – Current – After August 1997 | |

| Part Number | Description |

| 40673 | Continuous Clean Valve

(CCV) (Dwg. E9-1035) |

| 40661 | Continuous Clean Valve

(Design Retired – Use 40673) |

| 45545 | Valve, Air, 4-Way with

Push Button (Dwg. E9-1030) |

| 46855 | Electric Timer, Repeat

Cycle 100-240VAC |

| 46858 | Solenoid Valve, 4-Way

110VAC (Single valve – 2-Required) |

| 46853 | Solenoid Valve, 4-Way

220VAC (Single valve – 2-Required) |

| 45667 | -Repair Kit for

Solenoid Valves 46858 & 46853 |

| 46857 | Circuit Breaker, 2-Pole, 1.6 AMP |

| P-10937-BRZ | Muffler, ¼” NPTE |

| 46856 | Timer Base |

| Pressure Gauges | |

| P-20275-BRZ | Gauge, 2-1/2”, 200

PSI, Liquid Filled, Back Conn., Bronze |

| P-20275-SS6 | Gauge, 2-1/2”, 200

PSI, Liquid Filled, Back Conn., Stainless Steel |

| Siemens PLC Components | |

| 54002 | EEPROM, Siemens S7-200 |

| *PLC REPLACEMENT | PLC, Siemens S7-200 AC/AC/AC |

| *PLC REPLACEMENT | PLC, Siemens S7-200 DC/DC/DC |

| 54006 | -Siemens Operations Manual |

| 54007 | Siemens Display Module |

| 54003 | Expander Module, Siemens S7-200 |

| 46991 | Battery Cartridge S7-200 |

| 54003 | Siemens Control Output Module |

| Allen-Bradley PLC Components | |

| *PLC REPLACEMENT | PLC, MicroLogix 1200 |

| special order | Display, PanelView 300 |

| 81521 | Cable, PLC to Display |

|

*

when ordering replacement PLC’s the original Serial Number must be supplied |

|

| order to ensure that the PLC is programmed properly | |

| Misc. Automation Components Common to Either PLC | |

| 46984 | Power Supply, 110VAC/24VDC 2.5 amp |

| 54001 | Power Supply, 220VAC/24VDC 2.5 amp |

| P-11075-BRZ | Differential Pressure Switch |

| P-20992 | Pressure Transmitter,

1:1 Repeater (PMC) each |

| 45557 | Solenoid Valve, 4-Way, 24VDC |

| 45667 | -Repair Kit for P-41334 |

| P-12511 | Bulb, 32 V |

| 49001 | 2.5 AMP Fuse |

|

Lid Components (Previous – Cartridge Shaft Seal – Serial No. 1725 and Lower) |

|

| Part Number | Description |

| 46254 | Cartridge Ass’y,

Kynar, Buna-N, Retainer Ring & Instructions |

| 46255 | Cartridge Ass’y,

Kynar, EPT, Retainer Ring & Instructions |

| 46256 | Cartridge Ass’y,

Kynar, Viton® Retainer Ring & Instructions |

| 46257 | Cartridge Ass’y,

Teflon®, Teflon® Retainer Ring & Instructions |

| 42805 | Cartridge Ass’y,

Bronze, Buna-N Retainer Ring & Instructions |

| 42809 | Cartridge Ass’y,

Bronze, EPT Retainer Ring & Instructions |

| 42811 | Cartridge Ass’y,

Bronze, Silicone Retainer Ring & Instructions |

| 42807 | Cartridge Ass’y,

Bronze, Viton® Retainer Ring & Instructions |

| 42813 | Cartridge Ass’y,

Bronze, Teflon® Retainer Ring & Instructions |

| 42819 | Kit, Repair, Cartridge, Bronze, Buna-N |

| 42835 | Kit, Repair, Cartridge, Bronze, EPT |

| 42820 | Kit, Repair, Cartridge, Bronze, Viton® |

| 42823 | Kit, Repair, Cartridge, Bronze, Teflon® |

| 42802 | Bronze Cartridge |

| Consult factory Adapter, Drive | |

| 46235 | Inner Retainer Ring |

| 46230 | Outer Retainer Ring |

| 45522 | Lid, Machine |

|

* Retrofit kit includes, Packing wheel, lid,

adaptor, doctor plate, compressor bar, packing & fittings |

|

|

Retrofit Kit* – Convert from Cartridge Assembly to Adjustable Packing |

|

| 42960 | Retrofit Kit, Urethane Adjustable Packing |

| 42923 | Retrofit Kit, Teflon® Adjustable Packing |

| Purge Valve Components | |

| 45621 | Purge Valve with

Rotary Actuator – 1-1/2” Apollo |

| 45657 | Purge Valve Only – 1-1/2” 316SS Apollo |

| 45658 | Repair Kit – Purge Valve 45657 |

| 46027 | Purge Valve with

Rotary Actuator Ass’y. (Jamesbury) |

| F8-10009 | Purge Valve Actuator –

Repair Kit (Jamesbury) |

| 45661 | Rotary Actuator –

Apollo Double Acting -200 In/Lbs @ 60 PSI |

| 45663 | Rotary Actuator Repair Kit (45661) |

| 45675 | Mounting Kit – Actuator to Ball Valve |

| Obsolete Parts Still Supported | |

| 42904 | Adjustable Packing Wheel |

| 45403 | Lantern Ring -1-5/32” Lg. (1.15”) |