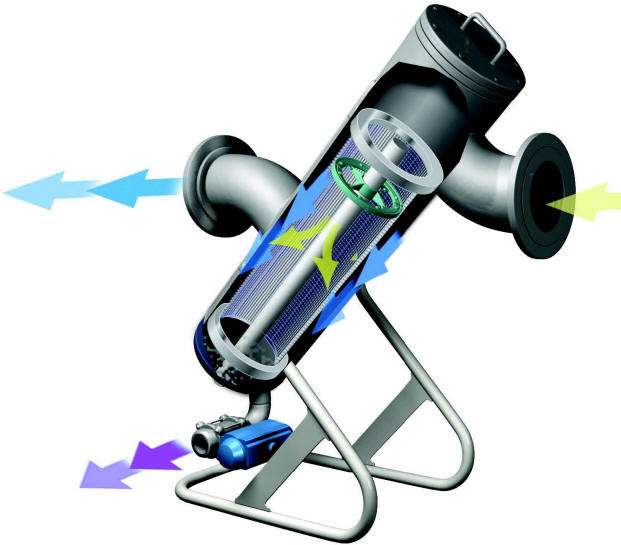

The concentrated solids within the purge

chamber are easily flushed form the housing in a matter of seconds

because it contains no horizontal surface.

The concentrated solids within the purge

chamber are easily flushed form the housing in a matter of seconds

because it contains no horizontal surface.

The quartered and spring loaded cleaning disc is designed to ensure even and consistent force against the element to maximize cleaning efficiency.

Mechanically cleaned strainers cost from $22,000 to $35,000 depending upon size and features. Please fill-out our inquiry form which will prompt for the design criteria required to provide a detailed proposal.

| Features | |

| • | No dynamic seals. |

| • | Minimal purge for low waste operation. |

| • | Easy in-line installation. |

| • | Continuous 24/7 operation. |

| • | Maintenance-friendly design means lower labor costs. |

| • | Eco-friendly. No bags to purchase, change or landfill. |

| • | Available in optional ASME Code. |

| • | <70 dB(A) airborne noise emission during normal operation |

| Specifications | |

| • | 30-150 PSI operating pressure, 150# RF ANSI flanged connections |

| • | Flow rates up to 1500 GPM per housing. (Can be multiplexed for up to 12,000 GPM.) |

| • | Operating temperatures up to 180°F |

| • | Designed for viscosities of water-like fluids |

| • | Maximum solids concentration: 200 PPM |

| • | Particle retention range: 150 to 1100 microns |

| • | All wetted components 316SS |

| • | Elastomers and plastics are Viton®/EPT and Delrin® |

| Requires | |

| • | 5 CFM of clean, dry, non-lubricated compressed air at 60 to 116 PSI |

| • | 115-230v/3ph/50-60Hz electrical service |